Why You Should be Using Insulated Concrete Forms

For many contractors, getting the foundation in before winter weather hits is a high priority for projects on the books.

One way you can put in a foundation is with insulated concrete forms (ICF). I personally used them on the foundation of my own home and am very impressed with the product.

Insulated concrete forms have improved over the years in design and popularity with architects, builders, and owners in both commercial and residential construction.

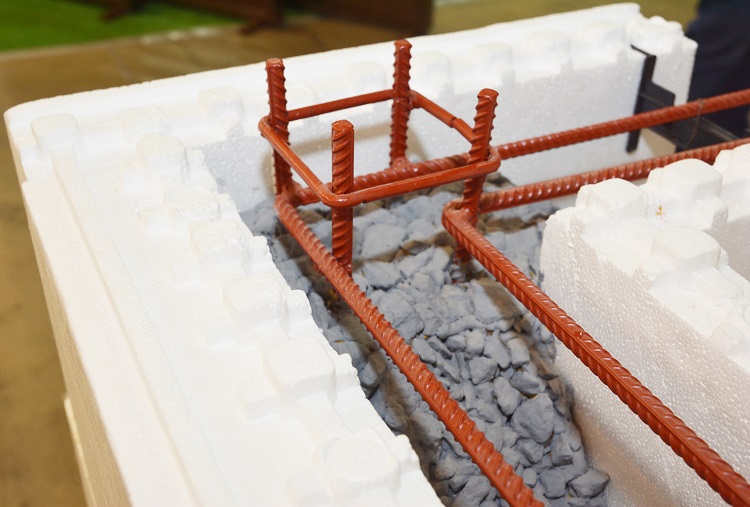

ICFs are insulated foam panels that are 48 inches long by 16 inches high and assembled like building blocks that lock in place to the desired wall height and length. Each is made of two polystyrene panels approximately 2 inches thick joined together with a high-density plastic webbing to create a concrete form that stays in place after the concrete wall is poured.

Any wall thickness can be achieved by a simple adjustment in the webbing. This webbing within the form is designed with saddles to hold the rebar in place, thus eliminating rebar tying. Furring strips embedded in the sides of the panel act as backing to fasten braces prior to pouring as well as backing for wall finishes.

Panels are formed to come in straight, 90- and 45-degree corners, radius, brick ledge, and double taper for the top of the wall.

There are many benefits of ICFs, including:

-

Superior insulation value.

-

A quiet environment to outside noise.

-

Durable and as structurally sound as solid concrete.

-

Elimination of drafts and air leaks.

-

A great surface to finish off with stucco on the exterior.

Some contractors like ICFs because they don’t have to handle, strip, and clean forms. ICFs are also much easier to handle due to their lightweight nature, which reduces the chances of back injuries. Installer-friendly ICF systems can make professional foundations easy for the beginner contractor.

Like any other product on the market, there are also some negatives to consider.

Insulated concrete forms are more expensive than a standard concrete foundation. However, when you add the framing and insulation, which is part of the ICF, the product is priced competitively.

If you are using an ICF foundation for your home, your building inspector will have you cover the walls with drywall before issuing occupancy due to toxic fumes caused by fire.

If you want to learn more about ICFs, there is plenty of information available on the pros and cons. ICF Resource is a great website to help answer your questions.

An insurance company that cares about you and insuring the things you wish to be insured.

Get a Quote> Find an Agent>